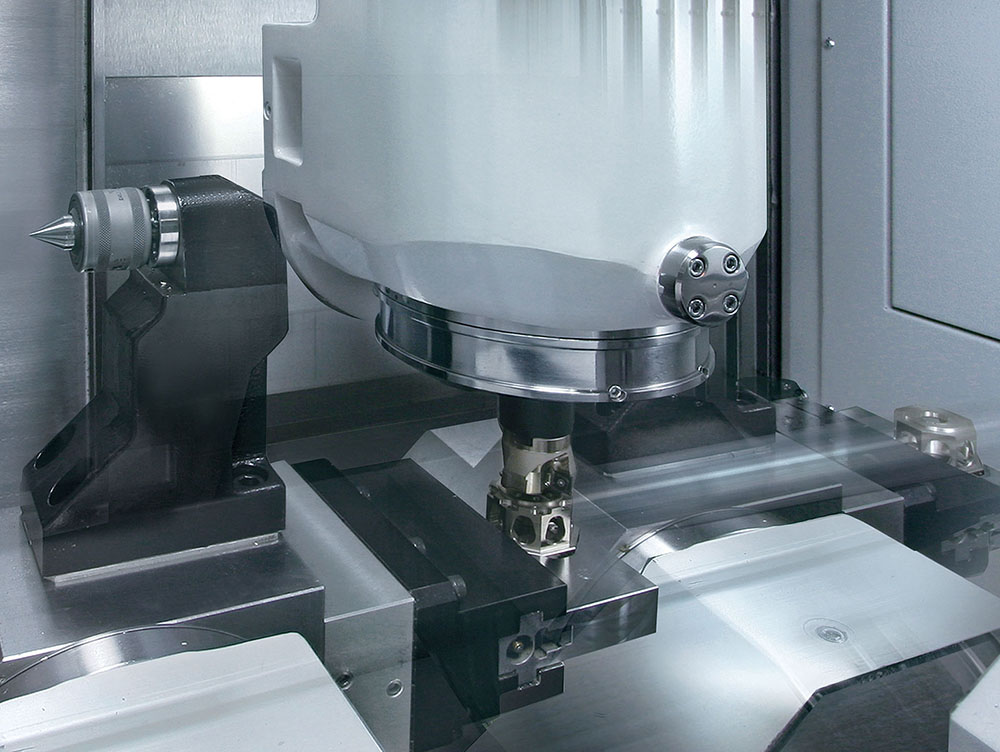

Ford Tool’s precision machining capabilities include 2-axis through 5-axis CNC multi-tasking lathes, vertical and horizontal mill machining centers with pallet changers, and a grinding department which includes CNC internal grinding, cylindrical grinding, centerless grinding, form grinding, surface grinding and EDM.

We also source required services such as heat treatment, finishing, coatings and more from our high-quality partners to enable “one stop service” for our customers. Ford Tool & Machining utilizes the latest inspection equipment, including Brown & Sharpe CMMs, to verify machined dimensions to ensure that we meet or exceed our customers’ quality requirements.

In order to ensure maximum quality control, all tooling operations, with the exception of heat treating, are done here at Ford Tool.